This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Offer

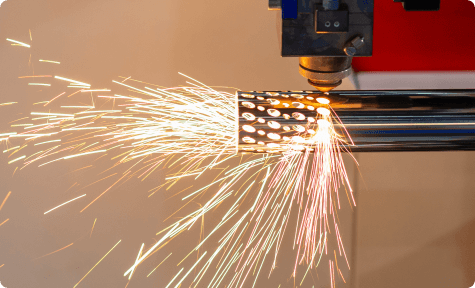

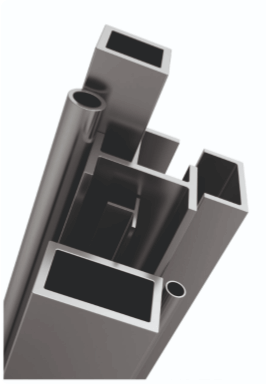

PIPES AND PROFILES LASER CUTTING

The capabilities of the FT-150 Fiber laser:

- So called “clean cut” without leaving any waste inside selected elements.

- Recognition of welding seams.

- Bevelling and chamfering of external and internal walls thanks to the rotating head.

- Thermal drilling and threading (M3-M12).

- Automatic loading and unloading.

Laser parameters:

Maximum loading length – 6500mm,

Maximum unloading length – 4500mm,

Round cross-section 12 – 152.4mm,

The side of the square section 12 – 125mm.

Thickness of cut-out elements:

Structural steel, acid resistant – 6mm,

Aluminum, zinc, brass, copper – 3mm.

The inquiry

should include:

1.

3D models of finished elements in ParaSolid, IGES or STEP formats.

2.

2D files for verification purposes.

3.

type of material and required quantity.

Our company is at your service. Every single client is important for us – we support small and big companies as well as individual clients. Our office is on duty 13 hours a day, where our planners and desing and technologists engineers are awaitnig. Well-developed machine park, the team of experienced specialists and the work of the production department in three shifts seven days a week which makes the efficient execution of the orders

FLAT SHEETS LASER CUTTING

The working sheet size of our laser cutters is 1500 x 3000 mm.

We cut materials to the thickness of:

- structural steel 25mm,

- acid-resistant steel 30mm,

- zinced steel 3mm,

- aluminum 30mm,

- brass 15mm,

- copper 12mm.

In order to precisely answer each request it should include:

1.

Material type and thickness.

2.

Required quantity.

3.

Technical drawing in .dxf or .dwg format, scale 1:1 in mm.

it is possible to prepare a drawing in the specified format, based on the customer’s detailed description of the detail.

BENDING SERVICE

Our company is equipped with two CNC bending machines, that enable us to bend complex elemennts and maintaining high tolerances.

We have modern Bystronic bending machines at our disposal, ranging from small, fast presses, to large and powerful ones.

The most essential bending parameters:

- maximum lenght of the bent element 3000mm,

- maximumpressing force 150t.

Hihg bending precision is achieved through an integrated CAM computer system, which enables optimization of the design process and bending simulation

The robotized bending station allows us to achieve 100% repeatability of operations. It minimizes the risk of error, which significantly shortens the production cycle of our clients and enables faster delivery of the product to the market.